How To Fix Motorcycle Engine Knock Your bike can automatically detune its engine, but there’s an easy fix. _by Eddie Hilgendorfen |May 10, 2023 Many modern motorcycles are designed to compensate for low-octane gasoline in an attempt to prevent motorcycle engine knocking. Unfortunately, the technology involved may also cause reduced performance, rough idle or […]

You are browsing archives for

Tag: piston

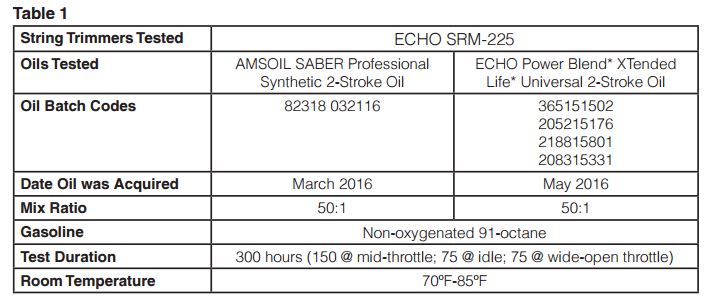

ECHO String Trimmer Technical Study

AMSOIL SABER® Professional Synthetic 2-Stroke Oil resisted performance-robbing deposits and maintained power and performance in ECHO string trimmers. Published September 2016 Overview Government mandates require modern handheld trimmers and other twostroke equipment to produce less exhaust emissions. To comply, some original equipment manufacturers (OEMs) design their equipment to run on leaner fuel/oil mixtures. Burning more air and […]