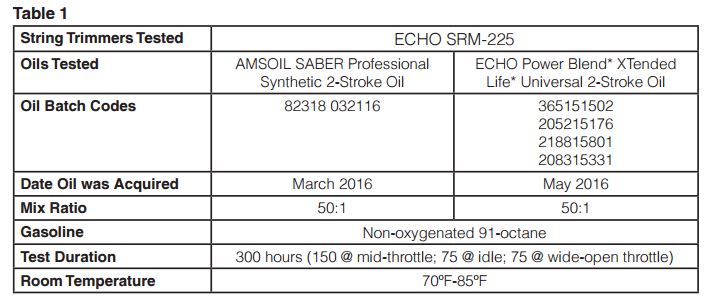

AMSOIL SABER® Professional Synthetic 2-Stroke Oil resisted performance-robbing deposits and maintained power and performance in ECHO string trimmers. Published September 2016 Overview Government mandates require modern handheld trimmers and other twostroke equipment to produce less exhaust emissions. To comply, some original equipment manufacturers (OEMs) design their equipment to run on leaner fuel/oil mixtures. Burning more air and […]

You are browsing archives for

Category: Engine Tests

Motorcycle Oil for your Motorcycle?

Motorcycle Oil for your Motorcycle? Ok, so it’s different but what makes AMSOIL better? Motorcycle engines and automotive engines function differently, and the lubricants that service them have different requirements. Six crucial differences between motorcycle and automotive engines are outlined below to illustrate why oil engineered for motorcycles is the best choice for your bike. […]

The Only Oil Choice for Turbos – Signatu

Visit us for all your oil needs: Synthetic Warehouse Sioux Falls 4610 W. 12th St. (12th & G right next to Wendy’s) New Challenges for Lubricants The increased slate of issues lubricants have to meet (or will have to) as technologies to lower emissions are required, place the burden of expertise on to the customer. […]

Now this would be fun!! Go for it!

The AMSOIL America Adventure is a 6-day competition in October of 2015. The competition will take teams on an adventurous route filled with intense competition with each evening ending in a new city. As part of the game, and the fun, teams will have no idea where they’ll end up for the night and will […]