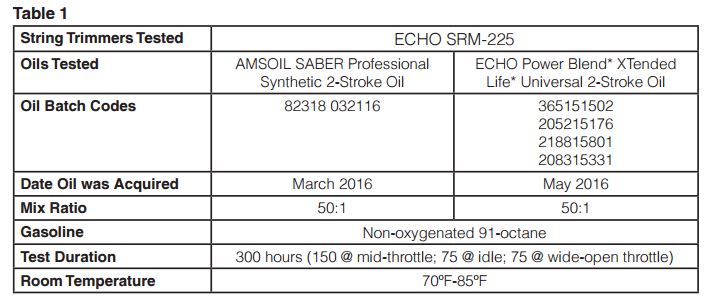

AMSOIL SABER® Professional Synthetic 2-Stroke Oil resisted performance-robbing deposits and maintained power and performance in ECHO string trimmers. Published September 2016 Overview Government mandates require modern handheld trimmers and other twostroke equipment to produce less exhaust emissions. To comply, some original equipment manufacturers (OEMs) design their equipment to run on leaner fuel/oil mixtures. Burning more air and […]

You are browsing archives for

Tag: 2-stroke

Troubleshooting a String Trimmer that ha...

Troubleshooting a String Trimmer that has Lost Power A few simple maintenance practices can help restore the performance of a faulty string trimmer (Weed Eater). Check the Age of the Fuel Today’s ethanol-containing gasoline can break down in relatively short time periods. If your blended fuel supply is more than two or three weeks old, […]

AMSOIL's Performance in Evinrude E-TEC 2

Outboard Protection at a Better Price AMSOIL is fast becoming the standard in the 2-stroke outboard oils just based on performance. Several OEM’s have a niche requirement for 2-cycle oil that often scares the customer into believing the OEM recommended oil is the only safe choice. While there are many inferior products out there, you […]