From the Filter Manufacturers Council:

Important information regarding – Transmission Fluid Evacuation Service

There has been a recent trend toward use of fluid evacuation systems in the automatic transmission service industry in lieu of traditional transmission service methods. These systems are used to pump the old fluid out of the transmission and to refill with fresh fluid. This avoids dropping the pan and draining the unit which can be time consuming and messy. The use of this method to replace the transmission fluid is a clean, efficient, and safe way to remove hot oil from a transmission. The

problem, however, is that often times it is mistakenly thought that this represents complete transmission service and that removal, and cleaning of the pan and inspection and servicing of the filter are unnecessary.

Some people believe that all transmission filters are backflushed clean every time the vehicle is turned off. This is a major misconception. Three-quarters of all transmission filters today are not a simple screen, they are made of felt. A felt filter CANNOT be backflushed. Felt holds dirt particles within tiny pores in the felt. It will not wash out or flush out. If a felt filter becomes clogged it must be replaced. Clogged filters restrict fluid flow, which lowers pressure to clutches and bands. This can cause slippage and eventual burnout of the transmission.

Service manuals and textbooks on transmission service recommend that a transmission filter be inspected and replaced, if necessary, as often as every 15,000 miles (24,140km), for severe service such as city driving, desert (hot dusty) driving, extreme cold, frequent short trips, trailer towing, and delivery service. In normal operating conditions the manuals recommend to inspect and replace the filter at least every 30,000 miles (48,280km). Even the newer vehicles with 100,000 mile (160,934km) drive train service warranties, the manufacturer recommends filter replacement if the vehicle sees severe service conditions.

There have been an increasing number of instances surfacing recently regarding transmission failures shortly after an evacuation service, without filter removal. At the time of a fluid evacuation service, there is no way to know the condition of the filterand how clogged it may be. The filters job is to collect and hold contaminants, (dirt, metal filings, friction particles, etc.), and prevent these particles from causing malfunction in such components as electronic force motors and solenoids. Today’s

transmissions are far more susceptible to malfunctions caused by fine dirt contamination. Without servicing the filter, there is no way to know if the filter is clean of debris or nearing capacity. If the filter is nearing capacity, transmission failure may not be far off. This is also a sign that there may be other internal problems in the transmission. Recognizing these warning signs could eliminate major service later.

Most of the transmission failures after an evacuation service have occurred primarily on relatively high mileage transmissions that have not been serviced in some time. One reason for this is that the sludge and dirt buildup within the transmission will not completely be removed during the service. When the new fluid (which has detergent properties) is placed in the transmission, over days and weeks, the internal

components begin to wash the insides of the transmission.

This sludge does finally work loose and settles in the transmission filter, clogging it up even further than it may have been before service. In these extreme cases, where service has not been performed in some time, changing the filter may not completely fix the problem. Some mechanics recommend a second service a few weeks after the first, replacing the filter again, which may be partially clogged due to the cleaning process in the transmission.

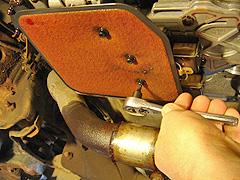

Even if the fluid evacuation method is desired to remove the used transmission fluid, the pan should be removed also, and an inspection should be made of the pan contents, fluid, and filter to determine the condition of the transmission. Aluminum filings in the pan or iron filings on the pan magnet are signs of internal wear and may

give light to potential problems in the transmission. Transmission service is performed for preventative maintenance. Evaluating the overall condition of the transmission by removing the pan should be part of this preventative maintenance also.

The Filter Manufacturers Council urges everyone to dispose of all used filters properly.